THANKS TO THE SERENDIPITY OF INNOVATION – AND 50 VATS OF ELECTRIFIED FLUID – OUR SPEAKER LOOKS LIKE IT’S BEEN TO SPACE AND BACK.

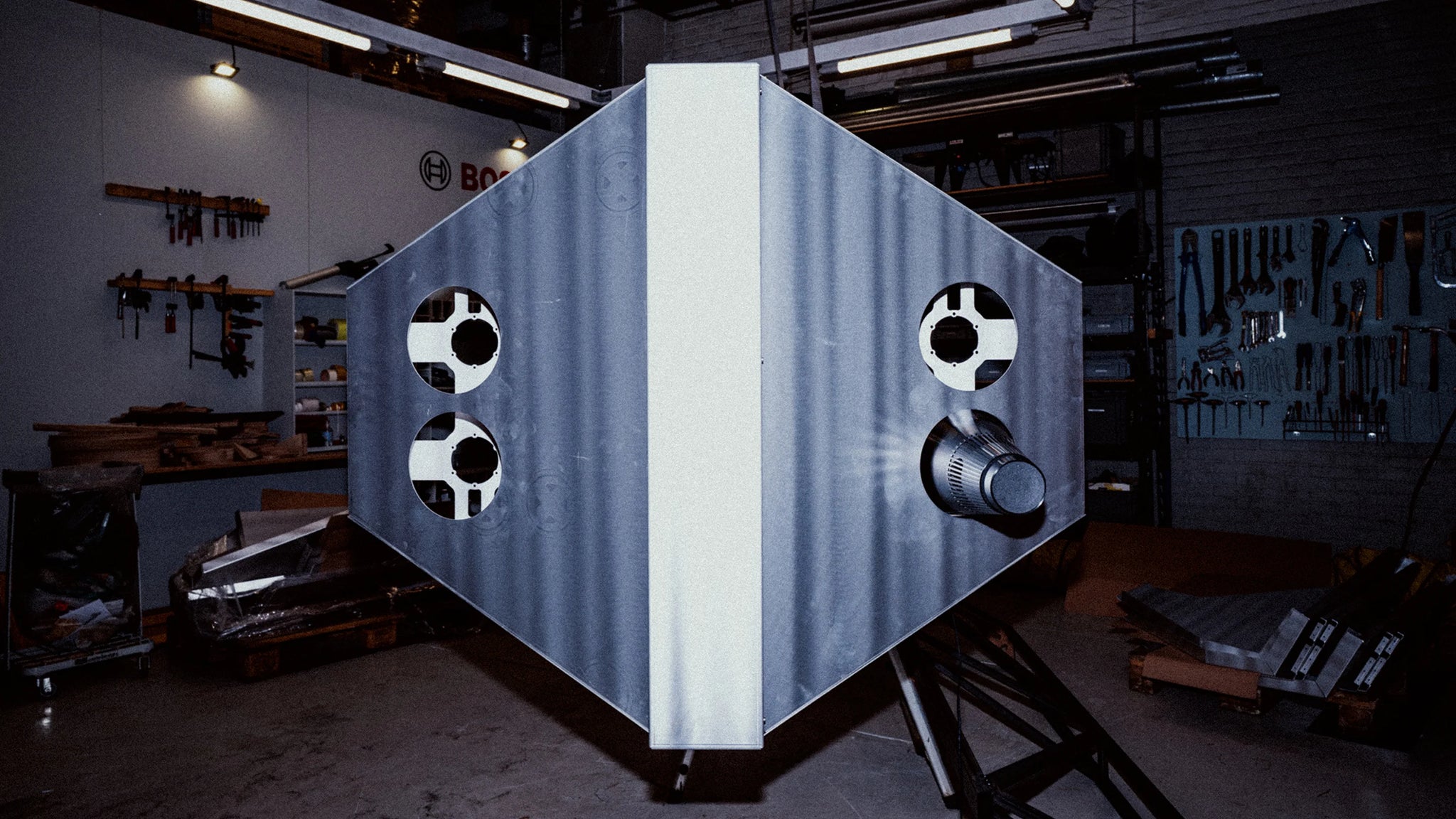

The Spaceshop includes four of Bang & Olufsen’s Beosound 2 speakers in its sonic propulsion drive. And launching alongside it is our space-worn, limited-edition take on the Beosund 2, finished in anodised aluminium.

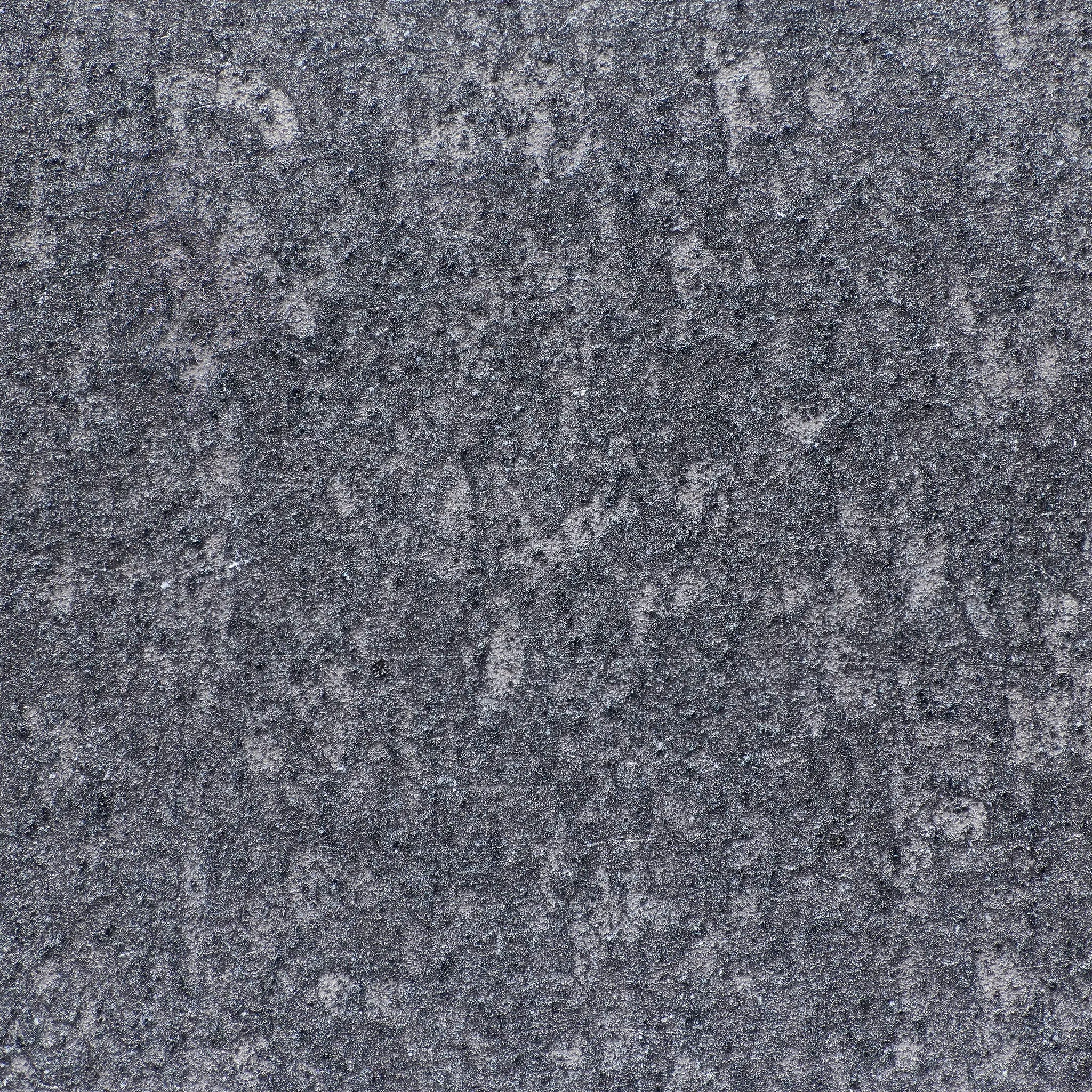

Our reworking of the speaker started with a moment of serendipity. “I was re-anodising a part that was supposed to end up with a standard deep black finish,” says Martin Schmidt, an anodisation specialist at Bang & Olufsen. “Instead, it came out with a textured, irregular surface, a mix of soft greys, grainy, swirly patterns, and darker streaks.”

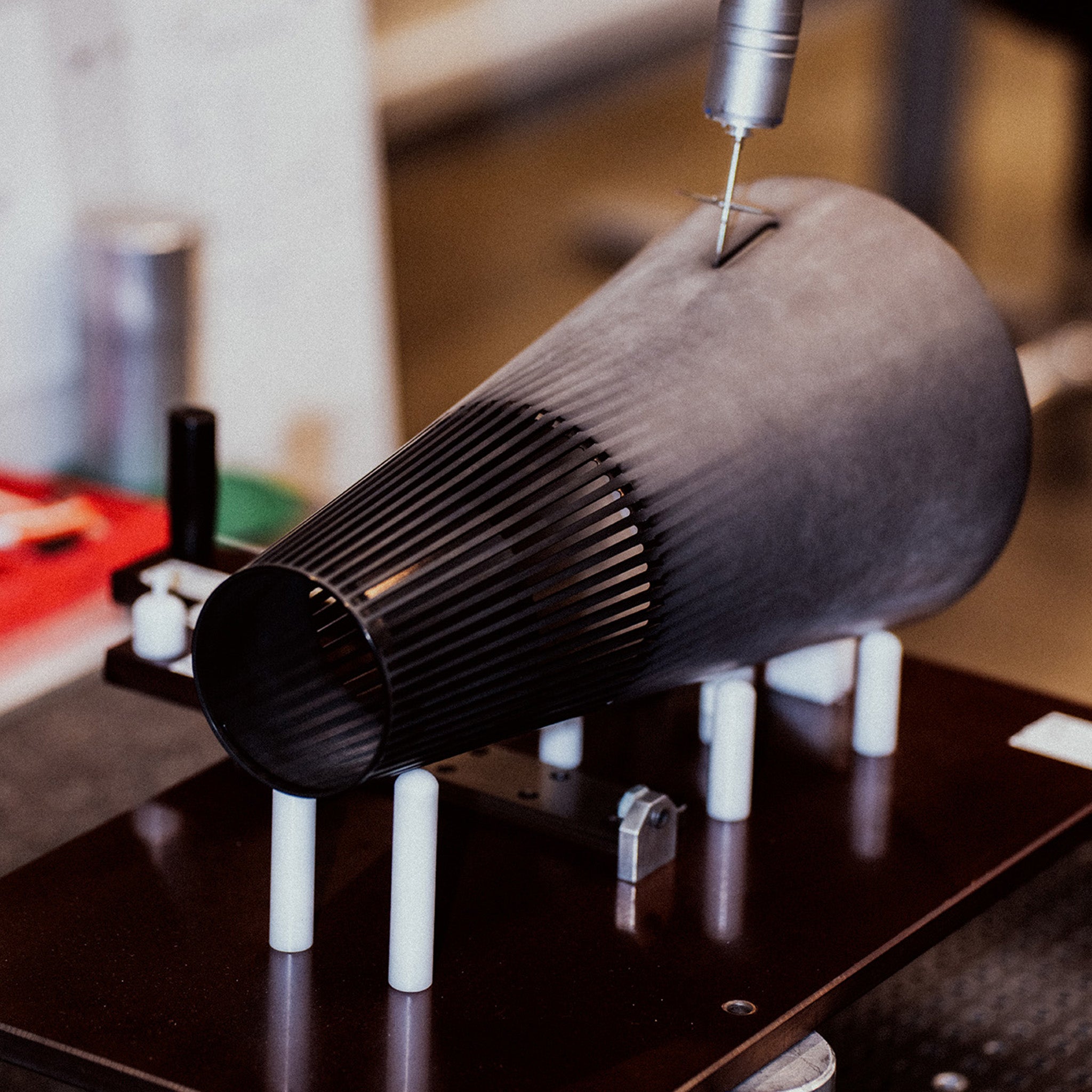

Kresten Bjørn Krab-Bjerre, Creative Director for Atelier at Bang & Olufsen, was working with his team on ways to simulate rocket burn on the Spaceshop speakers when Schmidt walked past carrying his misfire. “I showed Kresten the piece and he immediately saw something in it,” says Martin. “He liked the depth and unpredictability of the finish and asked whether it was possible to recreate.

“It had this fantastic, burned-out rugged surface, like it had been through the atmosphere and back,” says Kresten. The challenge was to reverse-engineer Martin’s happy accident in B&O’s anodisation lab, where fifty vats of electrified fluid – mostly water and sulphuric acid – form a long, burbling line through the centre of Factory 5 at the company’s Struer HQ.

“In its raw form, aluminium is an open structure,” says Kresten. “Left alone, it naturally oxidises to create a protective layer of boring grey. But in a controlled environment, you can re-open the pores, add colour, and seal it in with a layer of aluminium oxide. The result is a super beautiful metallic finish.”

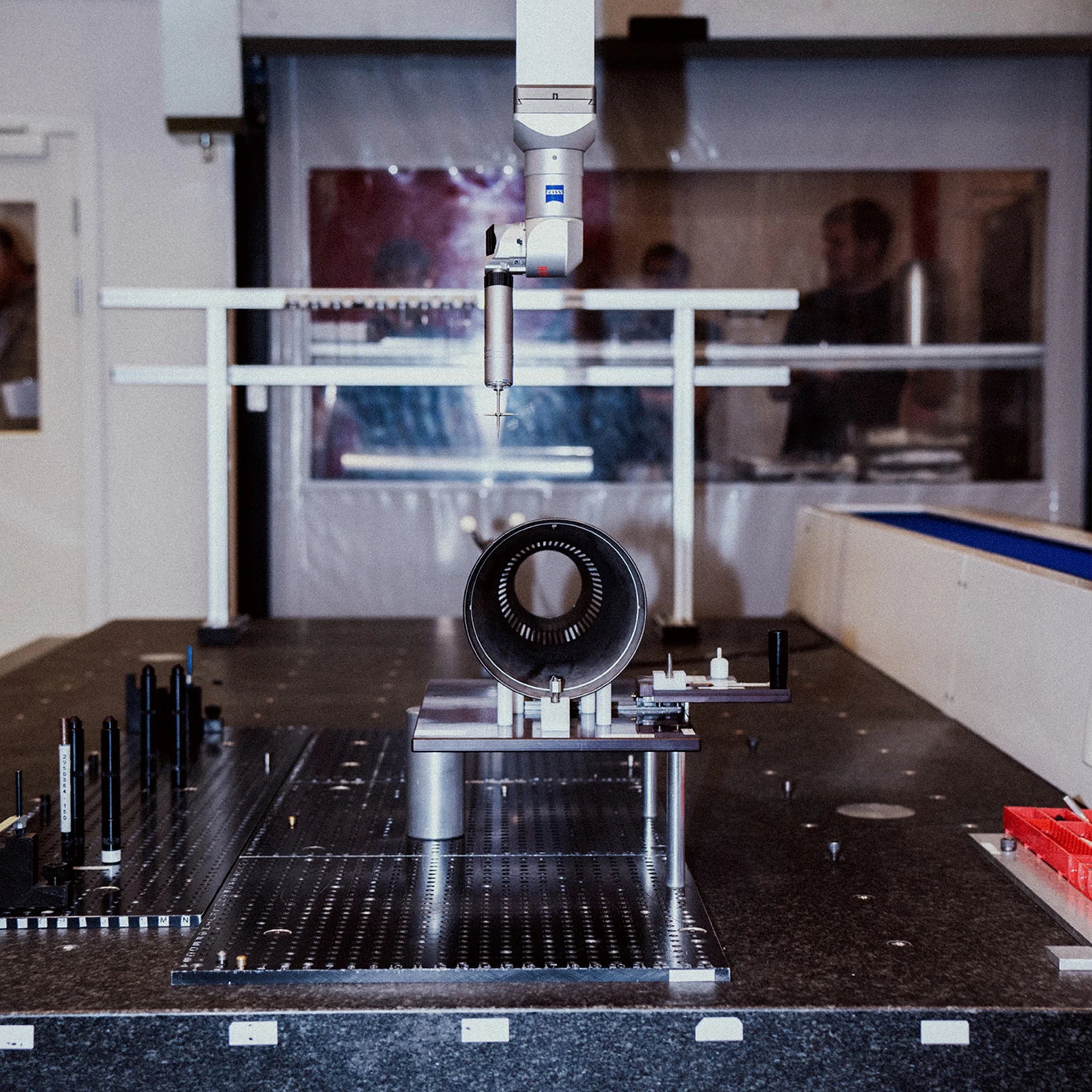

At Factory 5, mechanical arms dip aluminium parts into the chemical vats in a tightly choreographed sequence, directed from what the team calls the “command bridge.” When current hits the tank, oxygen ions bond with the metal’s surface to create a new outer shell of aluminium oxide.

That oxide layer is only one-tenth the thickness of a human hair but it’s permanent and protective, making the surface corrosion resistant and scratch proof.

Pre-anodisation adjustments in colour saturation and polish can shift the final finish from industrial matte to mirror sheen, ruby red to deep-space black. Or, if you try really hard, interstellar rocket burn.

Recreating this space-wear effect “kicked off a lot of internal experimentation,” says Martin. “But eventually we developed a way to reproduce it under controlled conditions. The process is very delicate. Let’s just say it involves some edge-case process parameters that most wouldn’t consider useful.”

Of course, there’s more to the Bang & Olufsen Beosound 2 Vollebak Edition speaker than rugged good looks. It delivers big, precise 360° sound from a compact, space-friendly footprint. Thanks to B&O’s Acoustic Lens Technology, you can put it anywhere and it’ll sonically adapt to its surroundings, whether that’s deep space or your kitchen.